- Home

- About Us

-

Products

-

for-prefabricated-elements

-

anteky-sh-anchor-system

anteky-sh-anchor-system

The SH-anchor system at the end of the round head embedded hanging nail is used for the hook, and the special duckbill buckle spreader is used to achieve a quick hook. The lifting load is transferred to the concrete via a circular end anchor at the other end of the nail. Installation requires the use of hemispherical rubber fixing nails while creating hemispherical grooves on the concrete surface so that the spreader can be hooked and lifted.

-

anteky-flat-lifting-system

anteky-flat-lifting-systemAnteky Flat lifting system is made up of flat anchor--a steel component (inset into the concrete) and ring clutch(a lifting component). The ring cluthc is locked to the anchor casted into concrete. Then prefabricated concrete component can be lifted and transported by a ring.

-

Anteky-thread-lifting-and-reinforcement-system

Anteky-thread-lifting-and-reinforcement-system

The thread lifting system consists of the permanently cast-in lifting anchor---socket anchors and the temporarily connected lifting equipments--lifting loops,rotary head lifting clutchs and cast-in loops.The main products of reinforcement system are Anteky wire loop boxes which are used to connect precast wallpanels to each other, or to a column.

Main Anchors,Nailing plate, lifting devices and wire loop box.

-

Formwork system

Formwork system

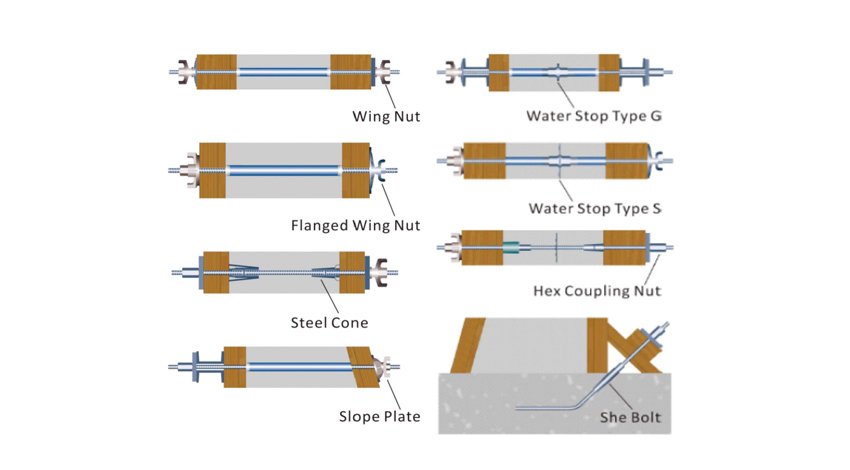

ANTEKY threadbar, together with matching accessories, are used in formwork construction.The coarse thread of threadbar doesnt run around the complete circumference of the bar. Hence the bar is not only insensitive against damages and dirt, but also self-cleaning. The high thread pitch allows a quick assembly and disassembly of the connecting and anchoring parts. And the high strength permites a high load capacity in relation to its low weight per meter.

-

Fixing-system

Fixing-system

The fixing system is made up of light duty anchors with low load capacities,mainly used for temporary fixings and applications without structural significance.

Main socket anchors,bolt anchors,bar anchors.

-

anteky-sh-anchor-system

-

Anchor channel system

-

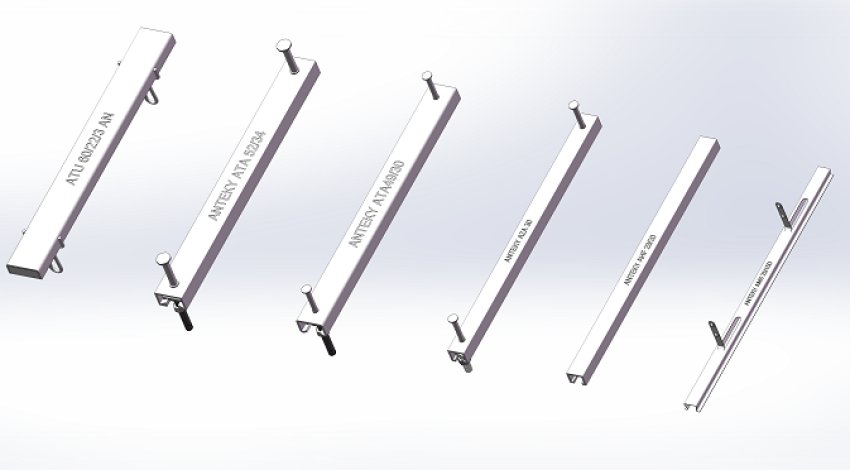

Anchor channel system

Anchor channel systemANTEKY Channels can be used for multiple types of connections, e.g. metro, high-speed rail, curtain wall, precast concrete constructions, stadium seat fixings, fixing railway tunnel cables,guide rails in lift installations, crane gantries or pipe fixations for bridges and so on.

-

Anchor channel system

-

Rock system

-

hollow-bolt

hollow-bolt

Hollow bolt is a kind of anchor rod made of steel pipe, which is hollow inside, and can be pressurized and anchored by pump slurry through the hollow part. It is often used for system support in tunnel arches and other moderately good geological surrounding rocks.

-

rock-bolt

rock-boltRock bolt is one of the most common forms of anchoring in tunnel construction, which is composed of steel bars and cement mortar. It is often used in tunnel side walls and other projects, and is more used for slopes with complete rock structures or temporary anchorage.

-

plastic-cover-bolt

plastic-cover-boltPlastic cover bolt is a kind of high-strength prestressed bolt, composed of anchors, bellows and bolts, which are widely used in reinforced concrete structure reinforcement, mine support reinforcement, tunnel reinforcement, bridge engineering, geotechnical engineering, water source well engineering and other fields.

-

hollow-bolt

-

other-products

-

operating-laror-protection-supplies

operating-laror-protection-suppliesProvide a full range of labor protection supplies required for the daily production and work of the partner enterprises, as well as related consulting, distribution, after-sales service and other one-stop services.

-

consumables

consumablesProvide customers with other building accessories and accessories used in the production process, one-stop supply of other spare parts required for the main products, with high adaptability of product specifications and sizes, and reduce procurement communication costs.

-

operating-laror-protection-supplies

-

for-prefabricated-elements

- Solution

- Service

- News

- Recruit

- Contact