-

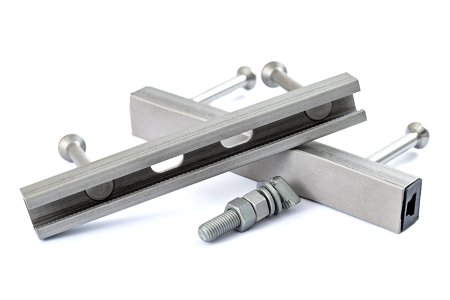

Cast-in Channel

-

Hot rolled

Hot rolledRead More

Hot rolledRead MoreMade by hot rolled of high-quality steel; Suitable for use in concrete pressure andtensile stress zones; High corrosion resistance steels available; Large range of types available for various requirements; Building Engineering Approval.

-

Cold rolled

Cold rolledRead More

Cold rolledRead MoreMade by cold rolled of high-quality steel; Suitable for use in concrete pressure and tensile stress zones; High corrosion resistance steels available; Large range of types available for various requirements; Building Engineering Approval.

-

Hot rolled

-

Products for Precast

-

Lifting System

Spherical Head Lifting Anchor SystemRead More

Spherical Head Lifting Anchor SystemRead MoreAnteky Spherical Head Lifting Anchor System, as a premier solution in construction hoisting, demonstrates exceptional performance through three key advantages: Versatile Engineering & Precision Design Its multifunctional design and precision-engineered structure ensure safe and reliable handling of diverse precast concrete elements, making it indispensable for architectural and infrastructure projects. Innovative Load-Management Technology As an industry leader, we integrate steerable and rotatable lifting devices that overcome traditional hoisting limitations—particularly critical for large-scale concrete utility tunnel installations. Modular Anchoring System The companion modular anchoring components cover full-spectrum requirements from standard loads to specialized conditions, delivering customized solutions for all lifting scenarios.

Lifting Anchor SystemRead More

Lifting Anchor SystemRead MoreThe Anteky Lifting Anchor System is fabricated entirely from steel plates. Its dedicated lifting fixture incorporates a rotary pin that must be rotated during hook connection to prevent accidental disengagement. When installing plate lifting anchors, the base plate becomes permanently embedded in concrete, secured by a dome-shaped former which simultaneously forms a concave recess in the concrete surface.

Socket Lifting SystemRead More

Socket Lifting SystemRead MoreThe Anteky socket lifting system is a highly efficient and reliable solution for precast component lifting. This system primarily consists of two parts: threaded sleeve lifting pins pre-embedded in concrete components and their matching lifting tools. Operators simply need to screw the lifting tool into the sleeve to lift and transport components. This design not only enhances the efficiency of the hoisting process but also significantly reduces safety risks caused by improper lifting operations.

Steel Core Lift LoopsRead More

Steel Core Lift LoopsRead MoreThe Steel Core Lift Loops embedded system consists of wire ropes permanently anchored within precast elements. After concrete pouring and when sufficient strength is achieved, formwork removal exposes the Steel Core Lift Loops in precast components, allowing direct connection to crane hooks. Upon completion of component hoisting, the Steel Core Lift Loops may be cut off or encased in concrete.

-

Connector System

Connecting LoopRead More

Connecting LoopRead MoreThe Anteky wire rope loop box system is a specialized solution designed for connecting walls between concrete PC components. This system is constructed from galvanized thin steel metal boxes and high-strength galvanized steel wire ropes, making it suitable for wall connections in precast concrete (PC) components. This design not only provides a reliable connection method but also ensures structural integrity and stability through its unique construction, which holds significant importance for improving construction efficiency and guaranteeing project quality.

Special ConnectorsRead More

Special ConnectorsRead MoreThe Anteky thermal insulation wall special connector is a critical component in insulated wall systems, primarily serving to connect the inner and outer wall panels with the intermediate insulation layer, ensuring the structural integrity and functionality of the wall. Selecting appropriate connector materials and designs can significantly enhance the thermal insulation performance and durability of the wall.

-

Formwork System

Formwork SystemRead More

Formwork SystemRead MoreThe Anteky Formwork System is a highly efficient and convenient template fixing device widely used in various fields such as prefabricated buildings, precast component production, and on-site installation. Through the use of high-performance neodymium iron boron permanent magnet materials and rational magnetic circuit design, it achieves powerful suction and flexible fixing capabilities.

-

Lifting System

-

Mechanical Splicing Systems

-

Upsetting Parallel Thread Rebar Coupler

Upsetting Parallel Thread Rebar CouplerRead More

Upsetting Parallel Thread Rebar CouplerRead MoreAnteky rebar coupling sleeve is a mechanical device used for connecting steel bars, suitable for joining large-diameter rebars. It ensures the connection can transmit both tensile and compressive forces, meeting structural design requirements.

-

Reinforcing bar peeling and Rolling Straight Thread Rebar Coupler

Reinforcing bar peeling and Rolling Straight Thread Rebar CouplerRead More

Reinforcing bar peeling and Rolling Straight Thread Rebar CouplerRead MoreAnteky rebar coupling sleeve is a mechanical device used for connecting steel bars, suitable for joining large-diameter rebars. It ensures the connection can transmit both tensile and compressive forces, meeting structural design requirements.

-

Upsetting Parallel Thread Rebar Coupler

-

Support System

-

Bridge Support BOB

Bridge Support BOBRead More

Bridge Support BOBRead MoreDuring the bridge construction process, the ANTEKY Bridge Overhang Bracket is often used as temporary support to bear the weight of the bridge, construction equipment, materials, and the load of labours during the construction period. It enhances construction efficiency, simplifies the construction process, and reduces reliance on heavy lifting equipment, thereby accelerating the construction progress.

-

System of Diagonal Bracing

System of Diagonal BracingRead More

System of Diagonal BracingRead MoreIn modern construction, the rapid and precise installation of prefabricated walls is key to improving construction efficiency and ensuring the safety of structure. To this end, we have introduced an innovative System of Diagonal Bracing specifically designed to optimize the support process for prefabricated walls. The large strut bracing system, through its unique design, can easily and quickly support prefabricated walls. Compared to traditional bracing methods, it significantly reduces labor requirements, making the installation process more efficient.

-

Bridge Support BOB