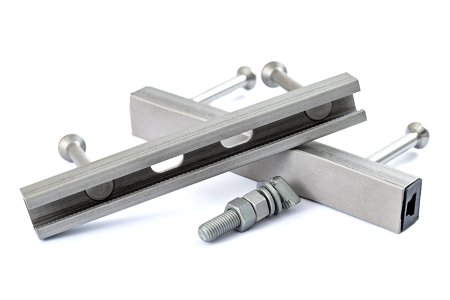

Our Double Shoulder Anchor is designed for thin wall panels, beams, columns, and similar components where sufficient anchorage depth is available.

Its uniquely shaped head prevents concrete spalling under lateral loads. The anchor features two semicircular notches on both sides of the plate, allowing the placement of additional inclined or reoriented reinforcement bars. This enables the safe rotation of thin-walled elements from horizontal to vertical positions during lifting operations.